Much has been written about the evolution of tyre manufacturing in the past few years, particularly about automation and smart factories and what this all means for tyre quality, performance, the environment and the consumer.

Triangle Tyre Co., Ltd, established in 1976, is known as one of the pioneers of low-carbon emissions and sustainability in the Chinese tyre industry, focusing on innovation, research and development, design, manufacturing and cutting-edge technologies.

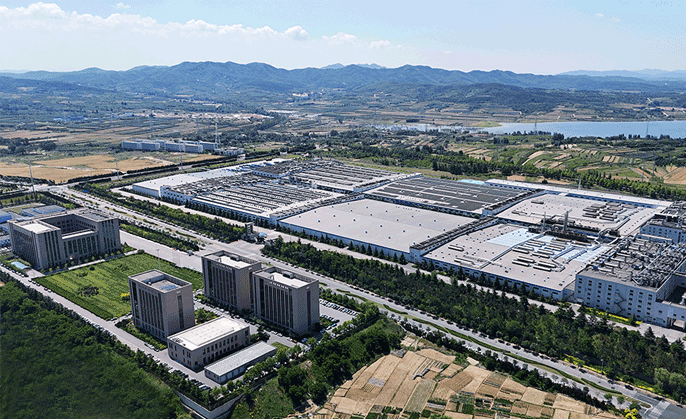

Triangle has one of the most advanced tyre manufacturing plants in the world located in Weihai, (Shandong), where 10 million tyres per annum are being produced with a workforce of just 300 people, in contrast to older technology plants where the labour required to make this volume of tyres would be in the thousands.

How is this achieved?

Here is a little insight as to why Triangle Tyre has made investments to lead technology deployment in tyre manufacturing and how it contributes to the product quality Triangle brand is known for.

Automation and Robotics

The Manufacturing Execution System (MES) determines everything Triangle does in manufacturing. The MES governs the movement of raw materials, conversion into components, the building of tyres through to final inspection.

From the moment raw materials arrive in the plant, they are almost exclusively handled and managed by robots and the MES (computer system) that determines the storage location and storage parameters.

Many raw materials are temperature sensitive and are stored in temperature-controlled environments. This means that even at this early stage, materials are managed to maintain their integrity and uniformity.

Along with the ERP (Enterprise Resource Planning) system, the manufacturing plan is determined based on demand, and materials are converted into tyre components.

Robots fetch the necessary raw materials, which are transported to various machinery without being handled by any human. The use of Robotics at these stages ensure that contamination of raw materials is significantly reduced, if not eliminated completely.

All processes are monitored and managed by the Intelligent Manufacturing System to ensure component materials remain within very tight tolerances.

At each step of the process the system can identify any variations and in most instances the interplay between machine and computer can correct any deviations. This is the early stage of machine learning and leveraging future AI technologies.

So, what does this mean for the final product?

Limiting human touch prevents contamination, which means components bond together better during the curing process, therefore the overall integrity of the tyre is not compromised yielding a significant improvement in repeatability and consistency in the end product.

Maintaining material gauge control leads to uniform components, which leads to improved balance. This ensures that the tyre uniformity will deliver against the design parameters for rolling resistance and safety.

This also leads to less balance weights being needed to balance tyres and rims resulting in further weight saving once installed. Driving down retailer costs, and additionally a reduced weight further improves rolling resistance.

The use of technology to drive uniformity in manufacturing has naturally led to a reduction in waste which in itself saves material and is a more environmentally responsible approach to making tyres.

The increased complexity of the world’s car parc and tyre size proliferation has also demanded greater flexibility in manufacturing.

The computerised nature of manufacturing and planning has driven for Triangle a greater ability to handle complexity with machines being able to assist in the minutiae of more diverse range of sizes and specifications to be planned.

The use of the technology of MES, ERP and robotics – what some call Industry 4.0 – has led to the capability in manufacturing being a real competitive advantage and has driven efficiency, productivity and hence greater control of conversion costs.

Environment and technology

In addition to manufacturing technology advancements, Triangle has also focused on the pursuit of environmental sustainability.

Triangle makes its own power using solar energy to drive down the reliance on fossil fuels.

Smart lighting is deployed throughout the factory to capture sunlight to deliver much of the light requirement in the plant.

In addition to this the factory captures and recycles water to deliver steam to the curing process, dropping the reliance on natural resources even further.

Wayne Foster, Global Marketing Director says: “At Triangle we care about the life of our employees, the communities we work in, the planet we live on and the customers we serve. Our investment in smart technology in manufacturing is just one of the ways we are ensuring our brand’s relevance and value well into the future.”

Share to

Revelant news

Copyright © 2019 - 2020 Triangle Tyre Co., Ltd 沪ICP备14019152号-1  沪公网安备 31019002000242号 All rights reserved Powered by Yongsy

沪公网安备 31019002000242号 All rights reserved Powered by Yongsy

DE

DE ES

ES FR

FR IT

IT US

US РФ

РФ 威路驰

威路驰 Diamondback

Diamondback