Carbon is an essential element for nature and living organisms, but a large amount of carbon has been released into the atmosphere in the form of carbon dioxide since the Industrial Revolution, causing global warming and posing great threat to human survival.

In December 2015, the Paris Agreement was adopted by nearly 200 parties during the United Nations Framework Convention on Climate Change's 21st Conference of the Parties in Paris. The Agreement requires all countries to set emissions-reduction pledges and mitigate climate change after 2020, with the goal of limiting global warming to well below 2 degrees Celsius above pre-industrial levels.

In order to achieve this, global emissions must peak as soon as possible and decline so as to reach a net-zero level in the second half of this century. And only by this way can we avoid the worst impacts of climate change such as ecological risks and challenges for survival to mankind.

During the NPC and CPPCC sessions this year, “carbon neutrality” and “emission peak” were incorporated into China's overall ecological civilization construction system, as stated in 2021 Government Work Report. Carbon reduction has become the consensus and common responsibility of the whole society.

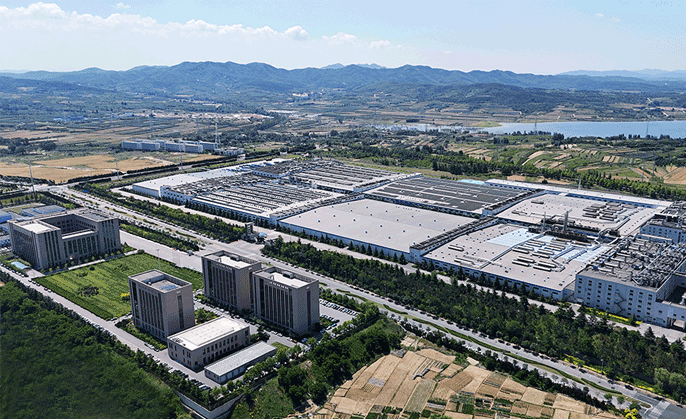

Triangle Tyre Co., Ltd. (Triangle for short) is one of the first advocates and pioneers of low-carbon and green development in China's tyre industry. For years of development, it has been leading the way on the path to carbon-reduction goals. It is committed to creating new production standards marked by low-carbon, green, environmental protection and efficiency, and it aims to provide environmentally friendly and energy-saving tyre technologies and products, and promote green manufacturing and green travel.

As early as 2009, Triangle released the Triangle Tyre Green Earth Initiative together with our partners, in which we called for low-carbon economy and lifestyle, and we pledged to serve the global market with continuous technological innovation and green products. In 2010, green technologies were introduced to the manufacturing of our new commercial vehicle tyres, including the direct use of solar energy, 100% recycling of water resources and curing waste heat recovery. The applications of information technology and automation also greatly conserved energy. This was a major move for Triangle to step on the path of low-carbon development.

Triangle is also the first in the industry to use the roof space of the plant to build a solar photovoltaic power station. Since it was put into use in June 2011, it has generated 25.08 million kWh of electricity, equivalent to the consumption of producing about 600,000 commercial vehicle tyres. We have also promoted the application of light guide lighting system in many of our enclosed workshops, saving 1.65 million kWh of electricity annually.

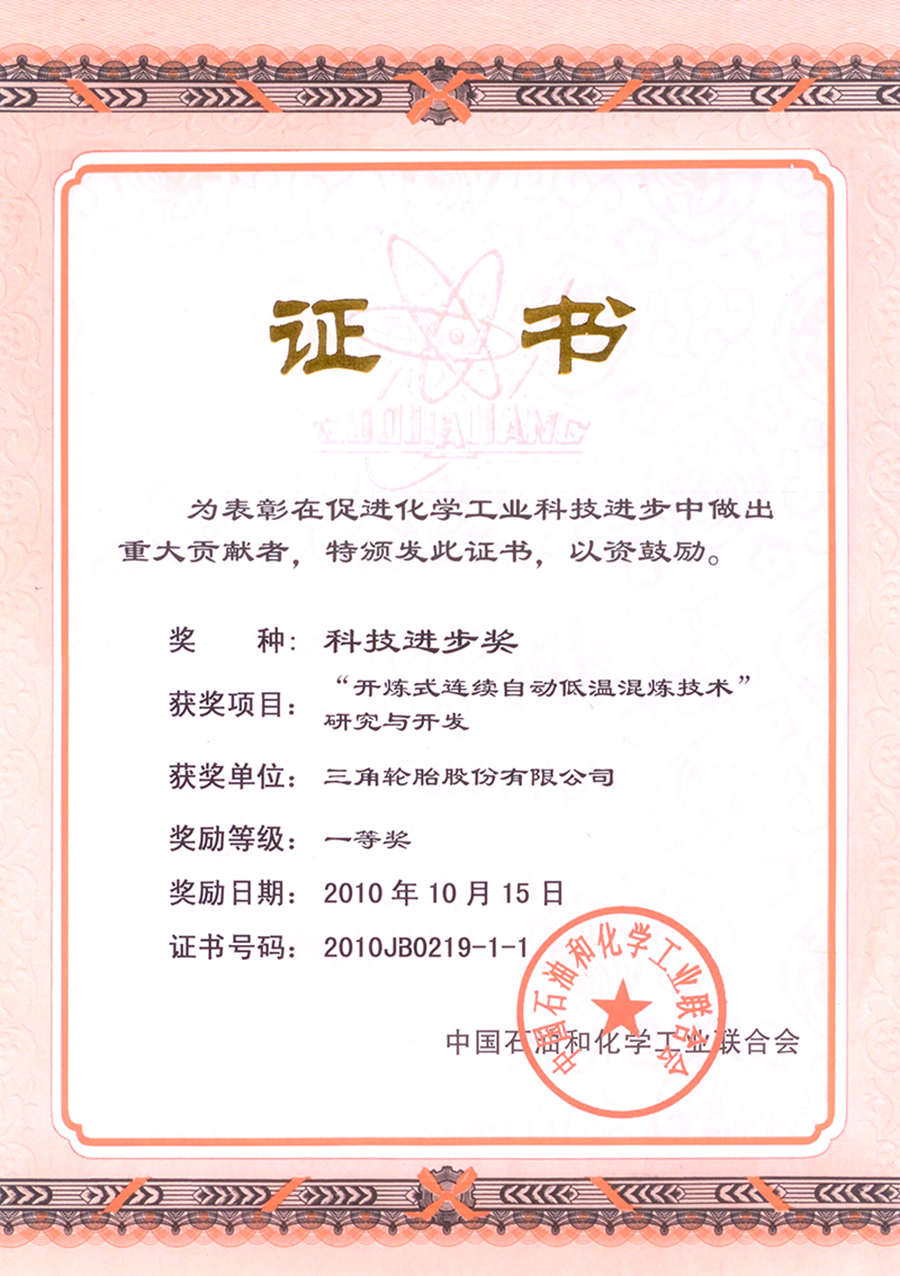

The reclaimed water reuse system adopted by Triangle can save water to the maximum extent and recycle the water used in the production process, so that the water consumption of the plant can be 82% lower than the industry access standard. Another widely applicable green technology in the tyre industry is our patented one-time low-temperature rubber mixing technique. By saving power by more than 10%, it has played a key role in promoting the industry's carbon reduction and technological progress.

During the 13th Five-Year Plan period (2016-2020), we have invested efforts in larger-scale energy-saving technical transformation. In this regard, we upgraded energy-consuming ban bury mixing and curing processes and equipment through technical transformation and innovation, and greatly improved the comprehensive utilization rate of electricity, gas and water. In the past five years, the company's energy consumption has decreased by 13%, with the total energy saving reaching 22,800 tons of standard coal.

In 2020, we replaced the disposable plastic mat, normally used in tyre manufacturing, with recyclable polypropylene fiber fabric, which can reduce plastic waste by more than 1,000 tons per year. This is part of the company's efforts to further protect the environment and promote the construction of green supply chain.

Triangle has been valuing ecological, green, low-carbon and safe operations from product R&D to design, and manufacturing, sales and supply chain. We strive to minimize the consumption of resources and energy, reduce carbon emissions and promote environmental protection.

Over the past three years, Triangle has fueled a steady increase in the share of green and safe tires with low rolling resistance, high wet-slip resistance and low noise. The performance of our products has reached the latest index requirements of the EU EcoLabel regulations and the SmartWay certification. Some are also classified as Grade-A tyres in roll resistance and wet-slip resistance. In 2019, the company was awarded “Green Design Demonstration Enterprise for Industrial Products” by the Ministry of Industry and Information Technology.

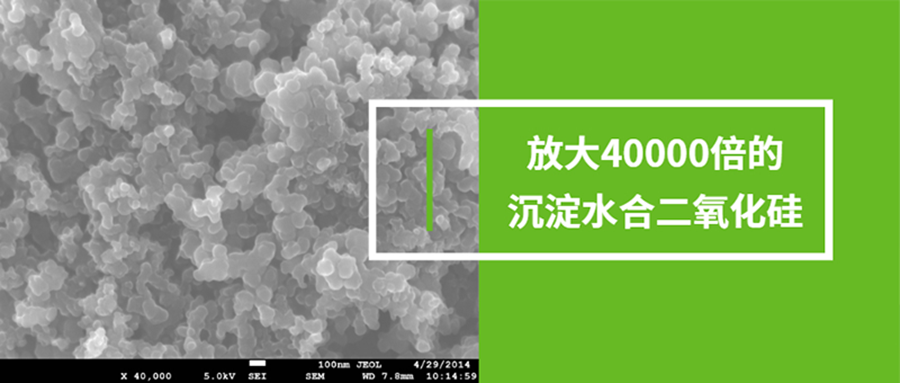

Triangle has been an active player in promoting the use of green raw materials in the tyre industry. The development and application of new green materials has been a priority for the company. Based on this, Triangle is working hard to develop non-toxic and non-hazardous tyres, adhere to REACH chemical compliance regulations, reduce reliance on petrochemicals and extend the use of renewable and recyclable materials. We are using environmentally friendly oils and peptize in all our product lines, and the proportion and type of silica is on the rise too. In addition, we have in-depth application research on new green materials such as vegetable oils, bio-based additives and rubber.

At present, Triangle is developing a new electromagnetic induction heating and curing equipment. It is expected to completely replace the traditional heat medium heat conduction method to solve the long-standing problems of low thermal efficiency and high energy consumption of the nitrogen/curing process. This revolutionary technology can cut down about 86% of energy consumption compared with the traditional process.

Tips:

To reach peak carbon emissions not at a certain point in time but in a plateau period, during which the total carbon emissions will still fluctuate up or down slightly and gradually see a steady downward trend.

Being carbon neutral means that the amount of carbon dioxide any person or entity emits into the atmosphere is the same as the amount of carbon dioxide they remove from the atmosphere by means of afforestation, energy conservation and emission reduction, industrial restructuring, etc.

Share to

Revelant news

Copyright © 2019 - 2020 Triangle Tyre Co., Ltd 沪ICP备14019152号-1  沪公网安备 31019002000242号 All rights reserved Powered by Yongsy

沪公网安备 31019002000242号 All rights reserved Powered by Yongsy

DE

DE ES

ES FR

FR IT

IT US

US РФ

РФ 威路驰

威路驰 Diamondback

Diamondback